Verderflex Ds500

Descubra la precisión, fiabilidad y flexibilidad de la bomba de tubo encamisado Ds500 uniéndose a la creciente comunidad de clientes de Ds500 Verderflex habilitada...

| Max. flow | 30 l/h |

| Max. discharge pressure | 7 bar |

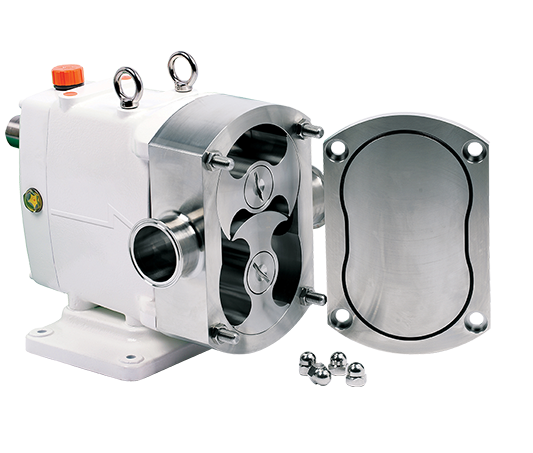

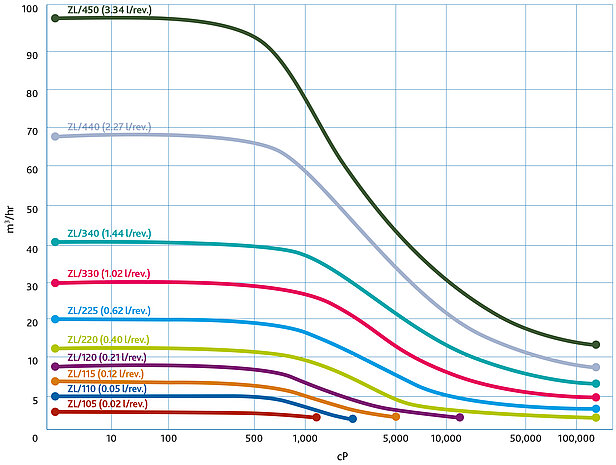

La serie ZL está diseñada para un amplio espectro de aplicaciones que abarcan las industrias láctea, alimentaria, de bebidas, farmacéutica, cosmética, panadera, de detergentes, de licores y química. Están diseñadas específicamente para transportar fluidos de baja a alta viscosidad con una manipulación suave del producto.

Cada serie de las bombas lobulares rotativas Packo es, en su campo, un estado de la técnica. Las bombas pueden equiparse con una gran variedad de características y rotores para adaptarse a casi todas las tareas de bombeo higiénico. Las bombas pueden personalizarse para obtener un funcionamiento o rendimiento óptimos para su proceso.

|

|

|

|

|

|

|

|

|

|

|

|

|

ZL105-002-20 |

ZL110-005-20 |

ZL115-012-12 |

ZL120-021-08 |

ZL220-040-12 |

ZL225-062-08 |

ZL330-102-12 |

ZL340-144-08 |

ZL440-227-12 |

ZL450-334-08 |

ZL560-1200-02 |

|

| Ver este tipo de bomba | Ver este tipo de bomba | Ver este tipo de bomba | Ver este tipo de bomba | Ver este tipo de bomba | Ver este tipo de bomba | Ver este tipo de bomba | Ver este tipo de bomba | Ver este tipo de bomba | Ver este tipo de bomba | Ver este tipo de bomba | |

| Max. flow |

20 l/min

|

50 l/min

|

96 l/min

|

168 l/min

|

287 l/min

|

434 l/min

|

612 l/min

|

864 l/min

|

1135 l/min

|

1670 l/min

|

3600 l/min

|

| Max. discharge pressure |

20 bar

|

20 bar

|

12 bar

|

8 bar

|

12 bar

|

8 bar

|

12 bar

|

8 bar

|

12 bar

|

8 bar

|

4 bar

|

| Port |

25 mm

|

25 mm

|

38 mm

|

50 mm

|

50 mm

|

63 mm

|

76 mm

|

100 mm

|

100 mm

|

125 mm

|

150 mm

|

| Speed |

1000 rpm

|

1000 rpm

|

800 rpm

|

800 rpm

|

700 rpm

|

700 rpm

|

600 rpm

|

600 rpm

|

500 rpm

|

500 rpm

|

300 rpm

|

| Descargar fichas técnicas | Descargar fichas técnicas | Descargar fichas técnicas | Descargar fichas técnicas | Descargar fichas técnicas | Descargar fichas técnicas | Descargar fichas técnicas | Descargar fichas técnicas | Descargar fichas técnicas | Descargar fichas técnicas | Descargar fichas técnicas | Descargar fichas técnicas |

Nuestros expertos pueden ayudarle a elegir la bomba adecuada para su proceso.

| Tipo | Litro / revolución | Presión máxima | Conexiones (mm) | Revoluciones máx. |

|

ZL/105 |

0.02 |

20 |

25 |

1.000 |

|

ZL/110 |

0.05 |

20 |

25 |

1.000 |

|

ZL/115 |

0.12 |

12 |

40 |

800 |

|

ZL/120 |

0.21 |

8 |

50 |

800 |

|

ZL/220 |

0.4 |

12 |

50 |

700 |

|

ZL/225 |

0.62 |

8 |

65 |

700 |

|

ZL/330 |

1.02 |

12 |

80 |

600 |

|

ZL/340 |

1.44 |

8 |

100 |

600 |

|

ZL/440 |

2.27 |

12 |

100 |

500 |

|

ZL/450 |

3.34 |

8 |

125 |

500 |

Descubra la precisión, fiabilidad y flexibilidad de la bomba de tubo encamisado Ds500 uniéndose a la creciente comunidad de clientes de Ds500 Verderflex habilitada...

| Max. flow | 30 l/h |

| Max. discharge pressure | 7 bar |

La gama PURE de Verderair está diseñada para trabajos pesados, productos químicos agresivos y condiciones de proceso severas, como la fabricación de paneles solares...

| Max. flow | 660 l/min |

| Max. discharge pressure | 7 bar |