Testimonial: Brewery Het Anker

“A minimal stock of spare parts, despite a large number of different pumps in various applications throughout our brewery."

Thomas Claeys, brewing engineer Het Anker

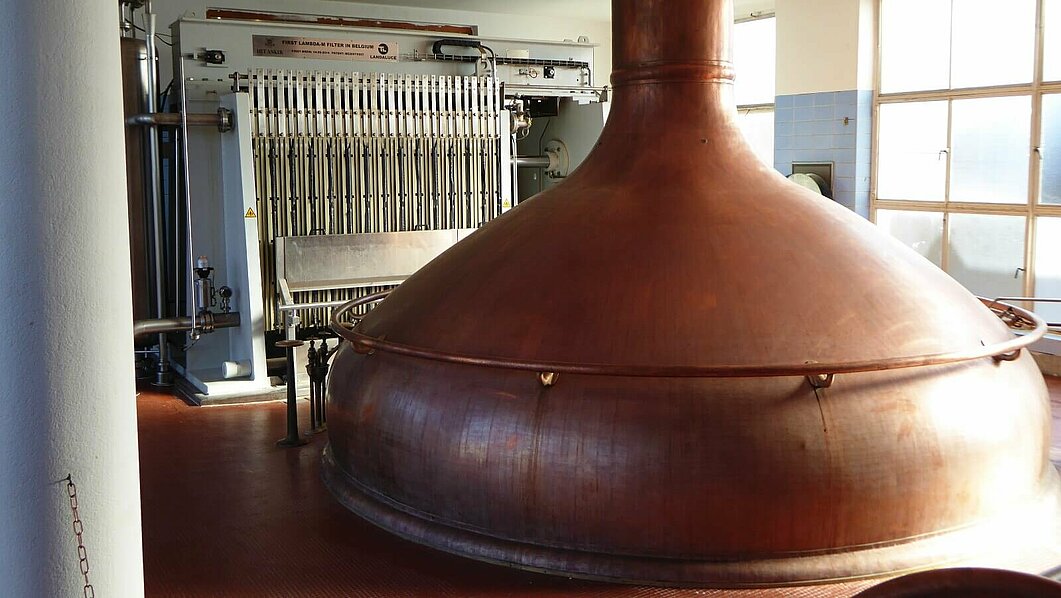

Thorough renewal for the city brewery of Mechelen

Het Anker is a city brewery located on the edge of the Mechelen beguinage. This brewery is known for its beers Gouden Carolus, Maneblusser, Cuvée van de Keizer, Boscoli and Lucifer beer. Besides the beers, the brewery also focuses on brewing malt wine for the production of whisky in Distillery De Molenberg.

Brewery Het Anker, for five generations in the hands of the Breedam family, is currently under the direction of Charles Leclef. In 2012 , the brewery underwent a thorough renovation, with a resolute choice for a complete standardization with Packo pumps.

Standardization with Packo pumps

During the renovation, the hanging copper brewing tanks were retained, but instead of a traditional mash kettle they installed a mash filter, which increased the productivity a lot. For pumping the mash and wort, they use the MCP2 Packo pumps, which are mainly characterized by their high efficiency and very low NPSH values. The high efficiency of these pumps mainly contributes to the "gentle" pumping of the mash, as a result of which shear forces do not affect the quality of the beer.

In addition to the modernization of the brewing hall, a number of CCTs (cylindrical-conical tanks) were added in the cold block, which creates more storage capacity. For this application a mobile Packo pump of type FP2 is used.

For the recuperation of the trub from the whirlpool, a CRP airhandling pump is used.

In order to expand the production capacity, the construction of a bottling plant in a nearby industrial park was started. In this bottling plant, which is mainly equipped with a number of pasteurs, holding tanks for the filler and a very reliable CIP installation, pumps are mainly used of the type FP2, CRP+ and for the larger volumes the MFP pumps.

Packo pumps across the board

Thomas Claeys, technical manager of the brewery, mainly refers to the very low stock of spare parts. Because, in spite of a wide variety of applications in the brewery, all the pumps have been designed with virtually the same mechanical seals.

In addition, Thomas also indicates that both the technical assistance of Packo and the quality of their pumps certainly contribute to the high reliability of the brewery.

At a glance

Packo pumps in operation for:

- Pumping of mash and wort

- Recuperation of the trub from the whirlpool

- Storage in waiting tanks

- CIP