Verderflex Ds500

The Ds500 cased tube pump, discover the precision, reliability, and flexibility by joining the growing community of IoT enabled Ds500 Verderflex customers. Explore our...

| Max. flow | 30 l/h |

| Max. discharge pressure | 7 bar |

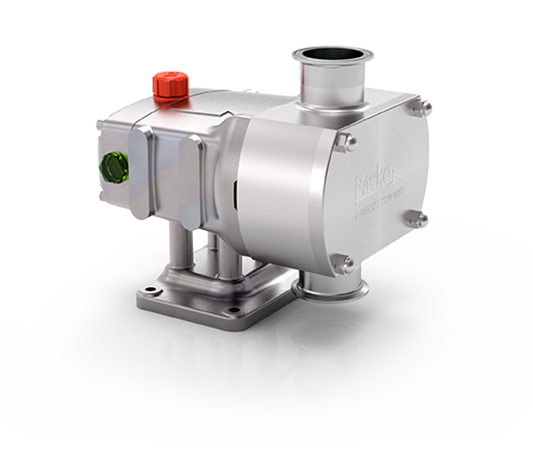

The Packo ZLC lobe pump pharmaceutical process pump is 3A certified. These perfectly cleanable pumps can be applied in the most demanding sterile applications in the pharmaceutical, biotech and cosmetic industry. All wetted parts in stainless steel 316L, 100% non porous and extremely smooth. Thanks to its crevice-free design and electropolishing as a final surface treatment, the ZLC pump is a perfectly cleanable and highly reliable component into your production process.

|

|

|

|

|

|

|

|

|

|

|

|

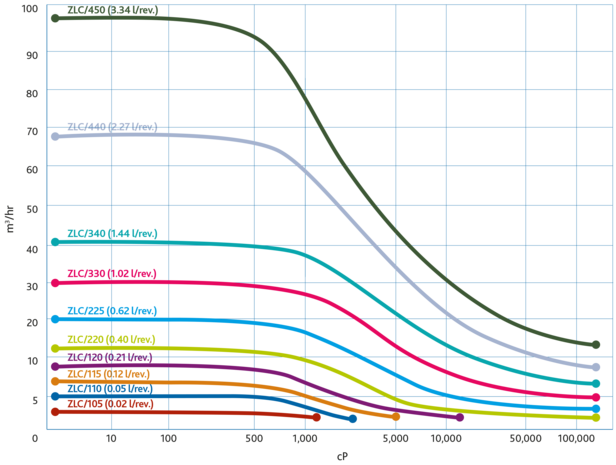

ZLC/105 |

ZLC/110 |

ZLC/115 |

ZLC/120 |

ZLC/220 |

ZLC/225 |

ZLC/330 |

ZLC/340 |

ZLC/440 |

ZLC/450 |

|

| View this pump type | View this pump type | View this pump type | View this pump type | View this pump type | View this pump type | View this pump type | View this pump type | View this pump type | View this pump type | |

| Max. flow |

42 l/min

|

83 l/min

|

125 l/min

|

133 l/min

|

200 l/min

|

333 l/min

|

500 l/min

|

700 l/min

|

1133 l/min

|

1670 l/min

|

| Max. discharge pressure |

20 bar

|

20 bar

|

12 bar

|

8 bar

|

12 bar

|

8 bar

|

12 bar

|

8 bar

|

12 bar

|

8 bar

|

| Port |

25 mm

|

25 mm

|

40 mm

|

50 mm

|

50 mm

|

65 mm

|

80 mm

|

100 mm

|

100 mm

|

125 mm

|

| Speed |

1000 rpm

|

1000 rpm

|

800 rpm

|

800 rpm

|

700 rpm

|

700 rpm

|

600 rpm

|

600 rpm

|

500 rpm

|

500 rpm

|

| Download datasheet | Download datasheet | Download datasheet | Download datasheet | Download datasheet | Download datasheet | Download datasheet | Download datasheet | Download datasheet | Download datasheet | Download datasheet |

|

Type |

Litre / revolution |

Max pressure |

Connections (mm) |

Max rpm |

|

ZLC/105 |

0.02 |

20 |

25 |

1.000 |

|

ZLC/110 |

0.05 |

20 |

25 |

1.000 |

|

ZLC/115 |

0.12 |

12 |

40 |

800 |

|

ZLC/120 |

0.21 |

8 |

50 |

800 |

|

ZLC/220 |

0.4 |

12 |

50 |

700 |

|

ZLC/225 |

0.62 |

8 |

65 |

700 |

|

ZLC/330 |

1.02 |

12 |

80 |

600 |

|

ZLC/340 |

1.44 |

8 |

100 |

600 |

|

ZLC/440 |

2.27 |

12 |

100 |

500 |

|

ZLC/450 |

3.34 |

8 |

125 |

500 |

The Ds500 cased tube pump, discover the precision, reliability, and flexibility by joining the growing community of IoT enabled Ds500 Verderflex customers. Explore our...

| Max. flow | 30 l/h |

| Max. discharge pressure | 7 bar |

The Verderair PURE is designed for heavy-duty operation, harsh chemicals and severe process conditions.

| Max. flow | 660 l/min |

| Max. discharge pressure | 7 bar |