MFF

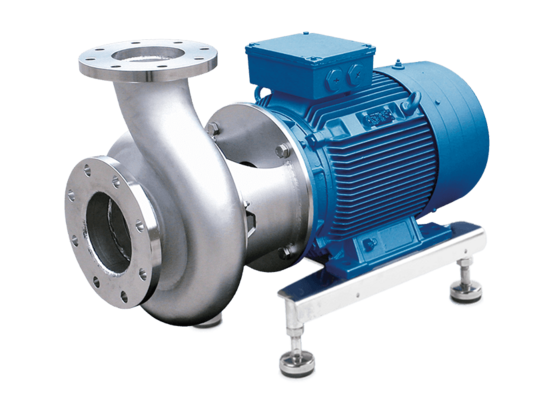

These robust pumps have stainless steel 316L investment cast pump casings and can be equipped with open, semi-open or vortex investment cast impellers in stainless steel 316L or similar. The pumps have a large clearance between the impeller and the pump casing and as a result they can handle solids and fibres without any risk of clogging. Thanks to its solid construction and electropolished design these pumps are the reliable component for your production process.The Packo pumps of the series MFF are used in a wide range of industries and applications. You can find them in just about all industries such as vegetable industry, water treatment and textile industry as well as in e.g. biogas, biodiesel and bioethanolapplications.

-

Properties

Property Max. flow 750 m3/h Differential head 30 m wc Max. Inlet pressure 12 bar Viscosity 500 cP Max. temperature 140 °C Impeller type Open or vortex Max. free passage 50 mm Max. drive power 250 kW Speed 1500/1800 rpm Available frequency 50 / 60 Hz Materials wetted parts Stainless steel 316L or similar Mechanical seal configuration Single bellow, single balanced, quench, double, pressurized barrier Available O-ring materials EPDM, FKM, FEP-FKM Connections BSP fittings. flanges according to EN1092-1/01 & 02. ANSI flanges Surface finish Industrial finish: welds are not hand polished. Final surface treatment: electropolished Certificates 1935/2004 EC. FDA. EAC. ATEX -

Description

These robust pumps have stainless steel 316L investment cast pump casings and can be equipped with open, semi-open or vortex investment cast impellers in stainless steel 316L or similar. The pumps have a large clearance between the impeller and the pump casing and as a result they can handle solids and fibres without any risk of clogging. Thanks to its solid construction and electropolished design these pumps are the reliable component for your production process.The Packo pumps of the series MFF are used in a wide range of industries and applications. You can find them in just about all industries such as vegetable industry, water treatment and textile industry as well as in e.g. biogas, biodiesel and bioethanolapplications.

Pump series MFF

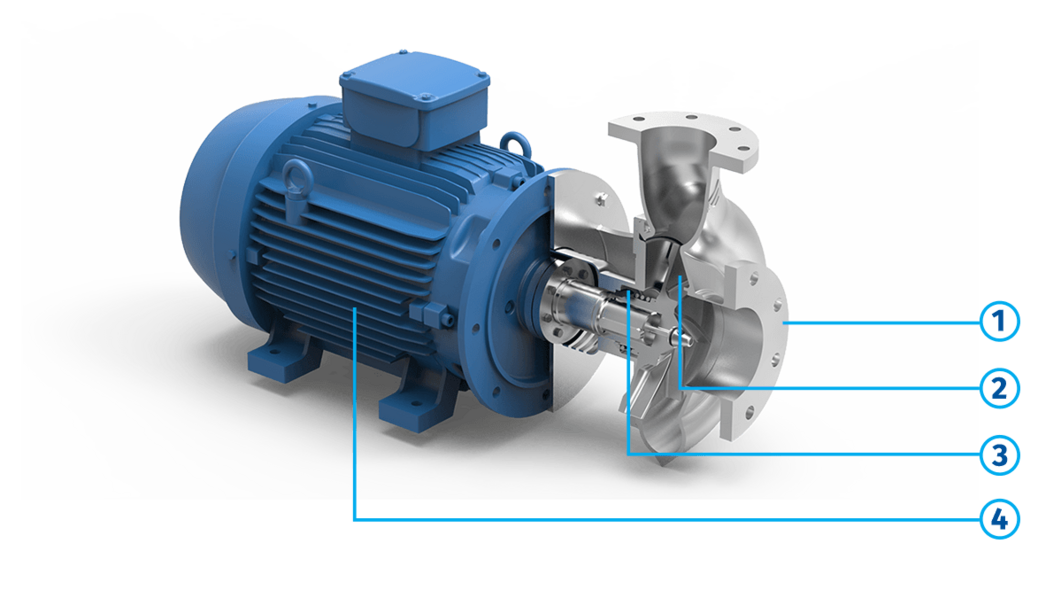

These robust pumps have stainless steel 316L investment cast pump casings and can be equipped with open, semi-open or vortex investment cast impellers in stainless steel 316L or similar. The pumps have a large clearance between the impeller and the pump casing and as a result they can handle solids and fibres without any risk of clogging.

Thanks to its solid construction and electropolished design these pumps are the reliable component for your production process.

- Investment cast stainless steel pump casings

- Large clearance between impeller and pump casing

- Large seal cavity to guarantee liquid circulation around the seal

- Monobloc execution with std. IEC motors

Application areas

The Packo pumps of the series MFF are used in a wide range of industries and applications.

You can find them in just about all industries such as vegetable industry, water treatment and textile industry as well as in e.g. biogas, biodiesel and bioethanol applications.

Typically the pumps are transferring liquids with fibres and solids coming from washing or blanching vegetables, potato waste, circulation of liquids on digesters, etc.

Your benefits

- Non-clogging, suitable for handling liquids with solids, fibres, foils and / or leaves

- Electropolished: higher resistance against corrosion

- Easy & robust construction and easy maintenance: less downtime

- Easy to install

- Solid impellers in investment cast material

- Standard components

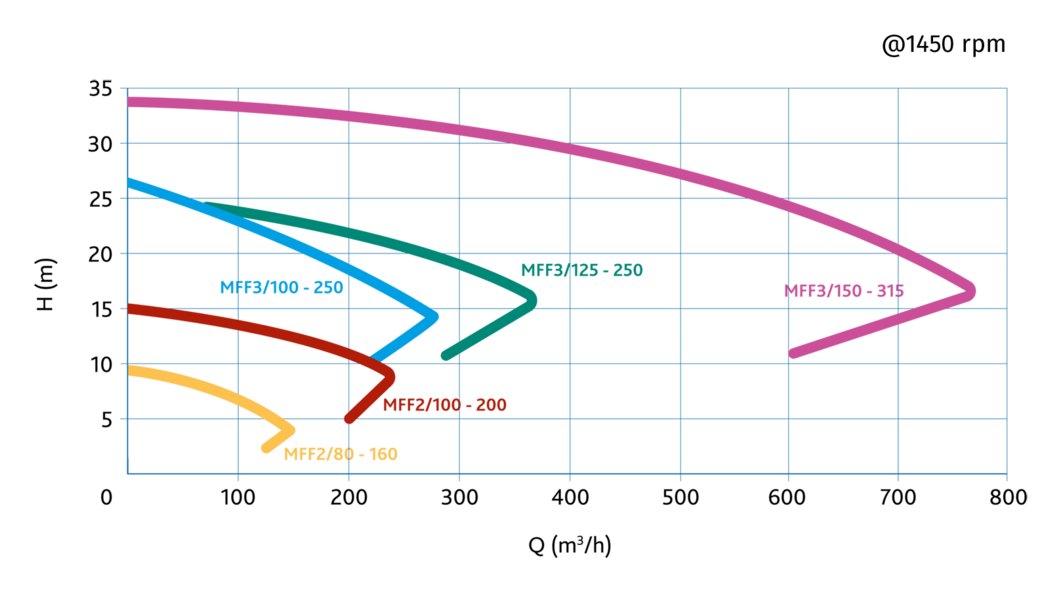

Performance Curves

Assembly and disassembly videos

Assembly video - configuration with bellow seal

Assembly video - configuration with sterile seal

Assembly video - configuration with quench and bellow seal

Assembly video - configuration with double seal

Disassembly video - replacement of bellow seal