Verderflex Ds500

The Ds500 cased tube pump, discover the precision, reliability, and flexibility by joining the growing community of IoT enabled Ds500 Verderflex customers. Explore our...

| Max. flow | 30 l/h |

| Max. discharge pressure | 7 bar |

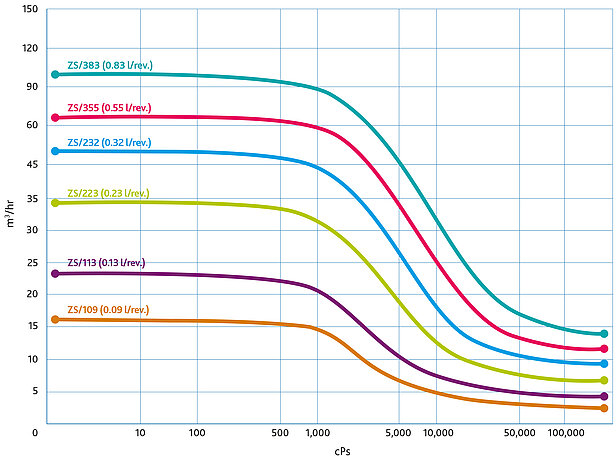

The ZS series can be supplied in diverse types to meet the customer’s requirements. The standard type of ZS Series, the ‘integral type’ consists of integral geared adaptor with B5, 4 pole motor directly coupled. This provides the most cost & space effective solution, due to the size of 4P motor and higher efficiency instead of coupled with 6P or 8P motors and convenient to get with a quick delivery time.

|

|

|

|

|

|

|

|

ZS/109 |

ZS/113 |

ZS/223 |

ZS/232 |

ZS/355 |

ZS/383 |

|

| View this pump type | View this pump type | View this pump type | View this pump type | View this pump type | View this pump type | |

| Max. flow |

270 l/min

|

390 l/min

|

575 l/min

|

800 l/min

|

1100 l/min

|

1660 l/min

|

| Max. discharge pressure |

12 bar

|

8 bar

|

12 bar

|

8 bar

|

12 bar

|

8 bar

|

| Port |

2.5" x 2" 2" x 1.5" mm

|

2.5" x 2" 2" x 1.5" mm

|

3" x 2.5" 2.5" x 2" mm

|

3" x 2.5" 2.5" x 2" mm

|

4" x 3" 3" x 2.5" mm

|

4" x 3" 3" x 2.5" mm

|

| Speed |

3000 rpm

|

3000 rpm

|

2500 rpm

|

2500 rpm

|

2000 rpm

|

2000 rpm

|

| Download datasheet | Download datasheet | Download datasheet | Download datasheet | Download datasheet | Download datasheet | Download datasheet |

The Packo ZS twin screw pumps were designed for pumping low to high viscous and gaseous liquids in hygienic applications in dairies, breweries, the pharma and cosmetics industry and bakeries. The ZS is the ideal positive displacement pump for gentle pumping of viscous liquids without damaging contained solids, such as fruit in yoghurt, nuts in ice cream, etc. Thanks to the wide range of allowable speed, the ZS pump can also be used as CIP+ pump, making a by-pass centrifugal pump redundant.

|

Type |

Litre / revolution |

Max pressure |

Connections (mm) |

Max rpm |

|

ZS/109 |

0.09 |

12 |

65*50 |

3.000 |

|

ZS/113 |

0.13 |

8 |

65*50 |

3.000 |

|

ZS/223 |

0.23 |

12 |

80*65 |

2.500 |

|

ZS/232 |

0.32 |

8 |

80*65 |

2.500 |

|

ZS/355 |

0.55 |

12 |

100*80 |

2.000 |

|

ZS/383 |

0.83 |

8 |

100*80 |

2.000 |

The Ds500 cased tube pump, discover the precision, reliability, and flexibility by joining the growing community of IoT enabled Ds500 Verderflex customers. Explore our...

| Max. flow | 30 l/h |

| Max. discharge pressure | 7 bar |

The Verderair PURE is designed for heavy-duty operation, harsh chemicals and severe process conditions.

| Max. flow | 660 l/min |

| Max. discharge pressure | 7 bar |