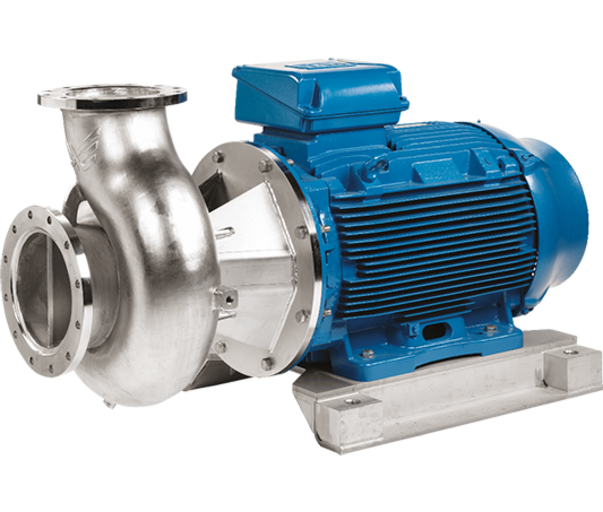

Pump with specially designed vane and larger pump casing for smooth and damage-free pumping of vegetables & potatoes.

Pumps for the vegetable and potato industry

A significant part of our core business is realized in this sector. In this way, we may call ourselves specialists in this market segment. Whether it is about damage free pumping of potatoes, vegetables, seafood, etc. or pumping frying oil to 190 °C, in all these cases Packo provides you a reliable solution. A well thought out design ensures smooth and damage free pumping without losing track of the hygienic aspect, durability or reliability.

The pumps also meet European regulation 1935/2004 EC, this way you can be sure that the food safety of your process is guaranteed.

Typical applications:

Typical applications can be found in the de-stoning, washing, cutting, pumping and blanching of vegetables and potatoes, among others. Packo also supplies solutions for the cleaning process (CIP) as well as for wastewater treatment.

Our clients do the talking

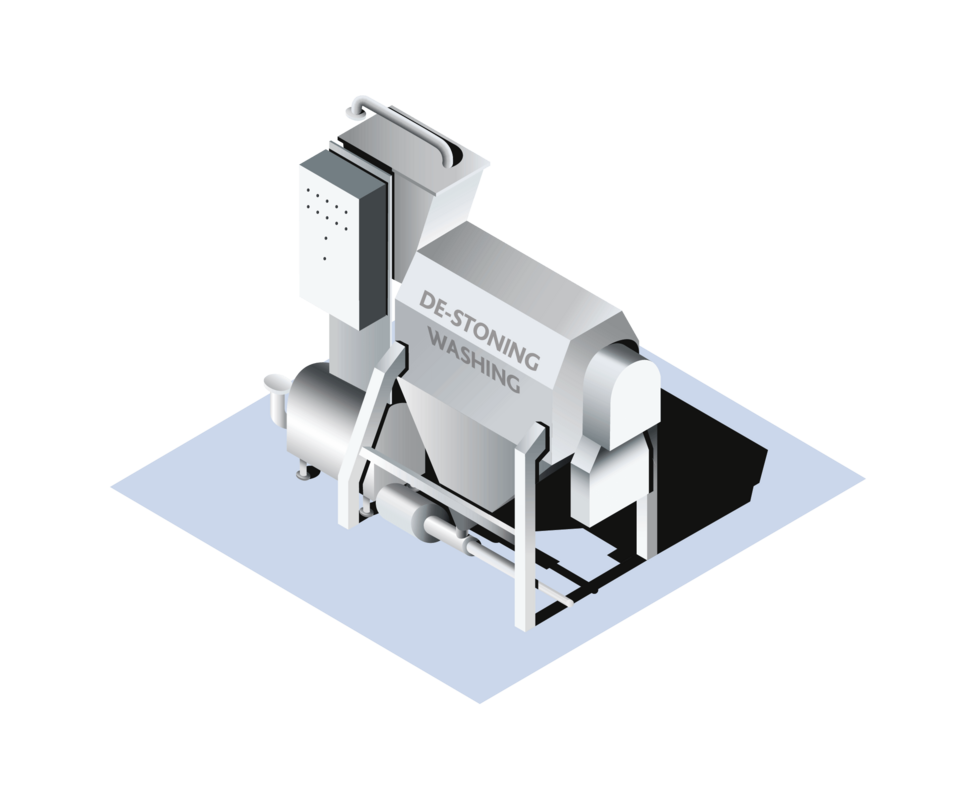

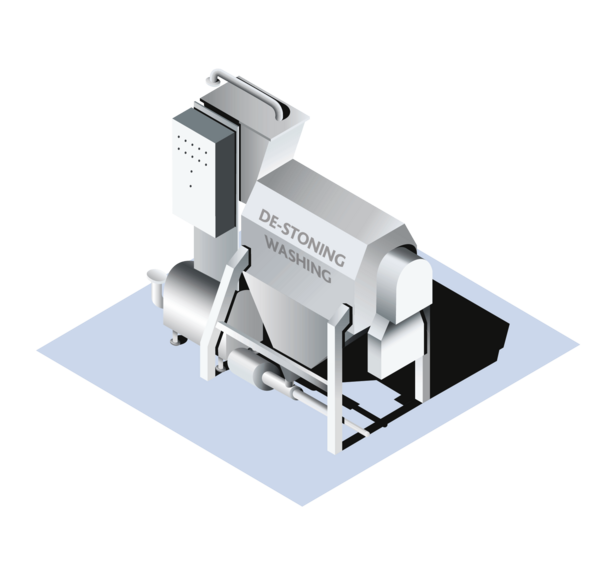

Pumps for de-stoning, washing and cutting

These applications mainly involve pumping water with the presence of vegetable and fibre residues, but also sand and clay particles, which can have an abrasive impact on the pump.

To extend the life of the pumps in this application area Packo offers a durable solution by providing a special coating in the sealing chamber so that a significantly longer service life is achieved! Pumps equipped with a vortex impeller are often used so that the risk of clogging is avoided!

All our pump series have a 1935/2004 EC certificate, so you can be sure that food safety is never compromised.

Discover our pumps for de-stoning, washing and cutting

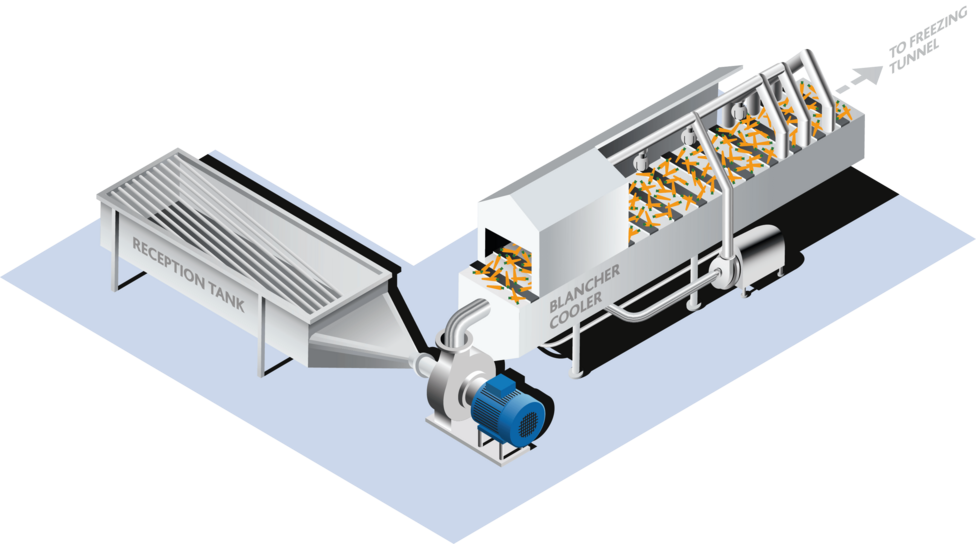

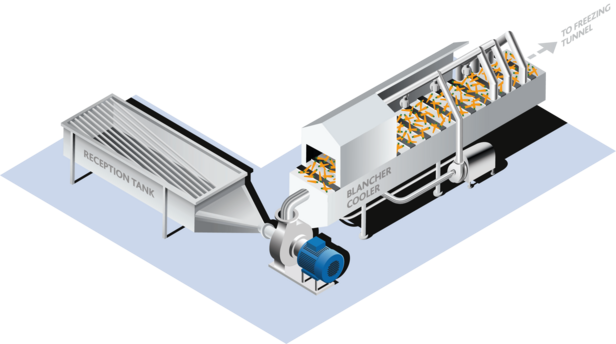

Pumps for blanching lines and transportation

From the moment of receipt, the vegetables are moved many times, either by conveyor belts or by hydraulic transport. It goes without saying that damage during vegetable transport must be kept to a minimum. With this in mind, the VPCP series was developed. With a specially designed vane, larger pump casing and a large passage it causes very low product damage. This is up to 50% lower than comparable pumps on the market.

During the blanching of vegetables, other factors are of great importance. It is a huge challenge to withstand extreme operating conditions such as high temperature (just below boiling point) combined with a very low water level in the blancher. Packo offers the most reliable solution on the market thanks to an enormous low NPSH of the pump which reduces the risk of cavitation. And this always combined with a high pump efficiency and therefore low energy consumption!

All pumps in this range are cf. 1935/2004 EC!

Pumps for waste water treatment

This is where pumps come into contact with water contaminated with residues of vegetables, sand, etc.

Pump series with specially equipped vortex impellers are available to offer a clog-free solution.

All pumps we offer for this purpose are produced in stainless steel with an industrial finish. This way, we offer a robust, reliable and corrosion-resistant solution to the sometimes aggressive waste water.