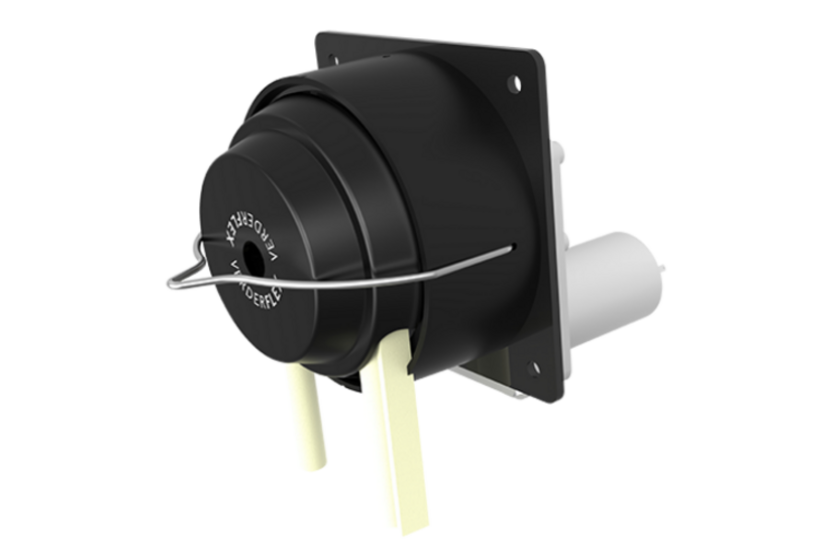

El bombeo en las industrias farmacéutica y cosmética

Al igual que en muchas otras industrias, las bombas pueden encontrarse en la industria farmacéutica y química. Muchas aplicaciones requieren, por ejemplo, una dosificación precisa, la dosificación de placas o la transferencia de diferentes fluidos.

Nuestras bombas higiénicas para la fabricación de productos cosméticos y farmacéuticos están ampliamente certificadas y disponibles en diferentes calidades de superficie. Nuestras bombas lobulares por ejemplo, ofrecen la mejor capacidad de limpieza y autovaciado.

Ejemplo de fluidos en la industria farmacéutica:

- Dosificación precisa de medicamentos

- Dosificación precisa de insignias de pequeño uso

- Desinfección de material de laboratorio

¿Busca una solución de bombeo?

Si necesita ayuda para decidir qué bomba es la mejor para su aplicación, no dude en ponerse en contacto con nuestros expertos en bombas.